Tel: 01992 414000 Email Us

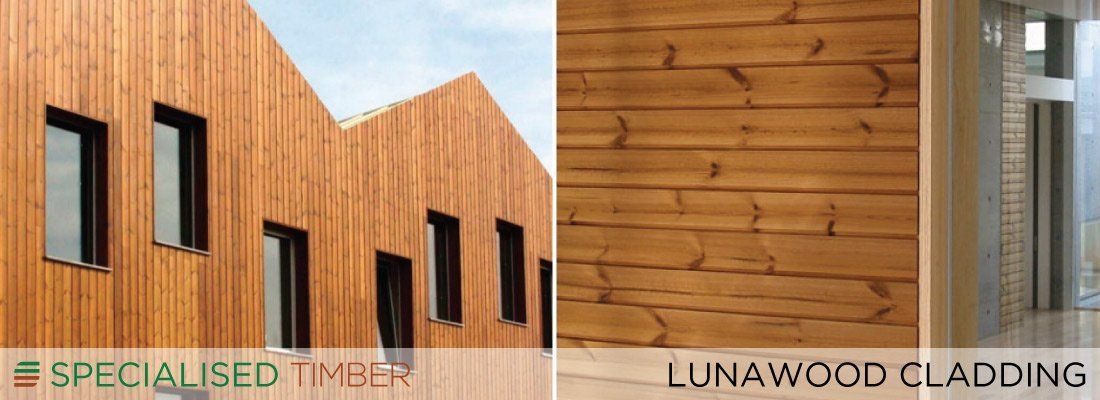

Lunawood Cladding

Lunawood

Timber Cladding

Lunawood Timber Cladding

Heat Treated Timber - LunaThermo-D

Heat Treated Timber - LunaThermo-D

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Slide Title

Write your caption here

Button

Slide Title

Write your caption here

Button

Slide Title

Write your caption here

Button

Slide Title

Write your caption here

Button

Construction companies - Civil engineering - Large scale housing or building projects - Architects

The thermal modification process utilises only high temerature and steam (up to 215 celcius). Therefore, Lunawood is completely natural and chemical free and can be safely burned or recycled after its long service.

We offer LunaTermo-D (where D stands for durability)

It has a darker brown tone and it's durability and stability are improved significantly.

The thermal modification process utilises only high temerature and steam (up to 215 celcius). Therefore, Lunawood is completely natural and chemical free and can be safely burned or recycled after its long service.

We offer LunaTermo-D (where D stands for durability)

It has a darker brown tone and it's durability and stability are improved significantly.

• Sugar chains in the wood are broken down and no longer support decay causing fungi

• Does not readily absorb water - greater dimensional stability and improved insulation properties (+25%)

• Resin is removed or dried - no risk of seepage

• Harmful emissions (such as formaldehyde) are eliminated - safe for indoor use

• Bacteria are killed, resulting in a sterile material

• Does not readily absorb water - greater dimensional stability and improved insulation properties (+25%)

• Resin is removed or dried - no risk of seepage

• Harmful emissions (such as formaldehyde) are eliminated - safe for indoor use

• Bacteria are killed, resulting in a sterile material

Species: Scandinavian Pine and Spruce

Appearance: Consistent colour of deep chocolate brown. Slowly grown with tight straight grain. Consistent colour throughout the thickness of the timber. Fine texture. Live inter-grown knots. free from pitch and resin.

Durability Classification: Durable - Class 2. BRE accredited service life of 30 years in cladding.

Density: Approx 450 kg/m3 at 8% moisture content

Dimensional Stability: Excellent

Environmental: PEFC Certified

Hardness: Little change from unmodified timber 1.65 on Brinel scale

Grade: Centre-cut - live knot A/B quality

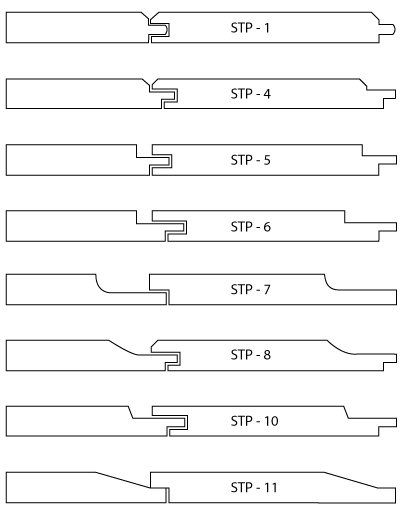

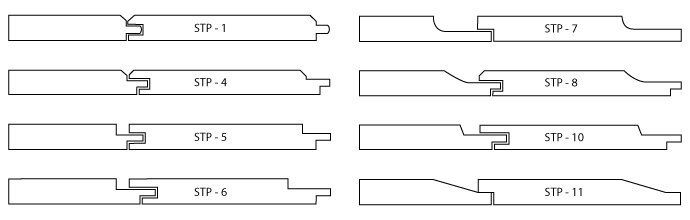

Dimensions:

Thickness: 25mm 32mm 38mm 50mm

Widths: 50mm to 200mm

Lengths: 3.0m to 5.7m

Finishing: Accepts application of stains and paints. Provides very stable substrate. Coating recommended in outdoor applications.

Working Properties: Can be sawn and planed with standard woodworking equipment. Pre-drilling for fixing location is recommended.

Extended curing times for glue, due to low absorption

Fixing: Austenitic stainless steel fixings are recommended

Appearance: Consistent colour of deep chocolate brown. Slowly grown with tight straight grain. Consistent colour throughout the thickness of the timber. Fine texture. Live inter-grown knots. free from pitch and resin.

Durability Classification: Durable - Class 2. BRE accredited service life of 30 years in cladding.

Density: Approx 450 kg/m3 at 8% moisture content

Dimensional Stability: Excellent

Environmental: PEFC Certified

Hardness: Little change from unmodified timber 1.65 on Brinel scale

Grade: Centre-cut - live knot A/B quality

Dimensions:

Thickness: 25mm 32mm 38mm 50mm

Widths: 50mm to 200mm

Lengths: 3.0m to 5.7m

Finishing: Accepts application of stains and paints. Provides very stable substrate. Coating recommended in outdoor applications.

Working Properties: Can be sawn and planed with standard woodworking equipment. Pre-drilling for fixing location is recommended.

Extended curing times for glue, due to low absorption

Fixing: Austenitic stainless steel fixings are recommended

Durability

Thermowood is rated as class 2, which is durable with a BRE expected service life of 30 years.

Dimensional Stability One of the benefits of this product is stability. The thermal modification process reduces the moisture content within the wood to help prevent movement in application.

Workability Due to thermal modification process this wood is easy to machine. Ensure that all corners are rounded to prevent splitting.

Fixing It is advised to fix thermowood with a nail gun whilst using a dampener to prevent damage to the face of the board.

Coatings and Treatments Due to the properties of this timber it is easy to coat with most standard coatings. Due to the natural durability we would advise against standard treatments as they will add no benefit to the product but we can offer fire retardant systems if required.

Weathering Thermowood will weather to a silver/ grey colour if left uncoated.

Certification Thermowood is PEFC certified.

Standard Grades Available Redwood or Whitewood (This is dependent on section size and production mill)

Dimensional Stability One of the benefits of this product is stability. The thermal modification process reduces the moisture content within the wood to help prevent movement in application.

Workability Due to thermal modification process this wood is easy to machine. Ensure that all corners are rounded to prevent splitting.

Fixing It is advised to fix thermowood with a nail gun whilst using a dampener to prevent damage to the face of the board.

Coatings and Treatments Due to the properties of this timber it is easy to coat with most standard coatings. Due to the natural durability we would advise against standard treatments as they will add no benefit to the product but we can offer fire retardant systems if required.

Weathering Thermowood will weather to a silver/ grey colour if left uncoated.

Certification Thermowood is PEFC certified.

Standard Grades Available Redwood or Whitewood (This is dependent on section size and production mill)

Here to help - call us on 01992 414000

©

Specialised

Panel Products Ltd. Registered in England & Wales under 3500652 -

Privacy Policy